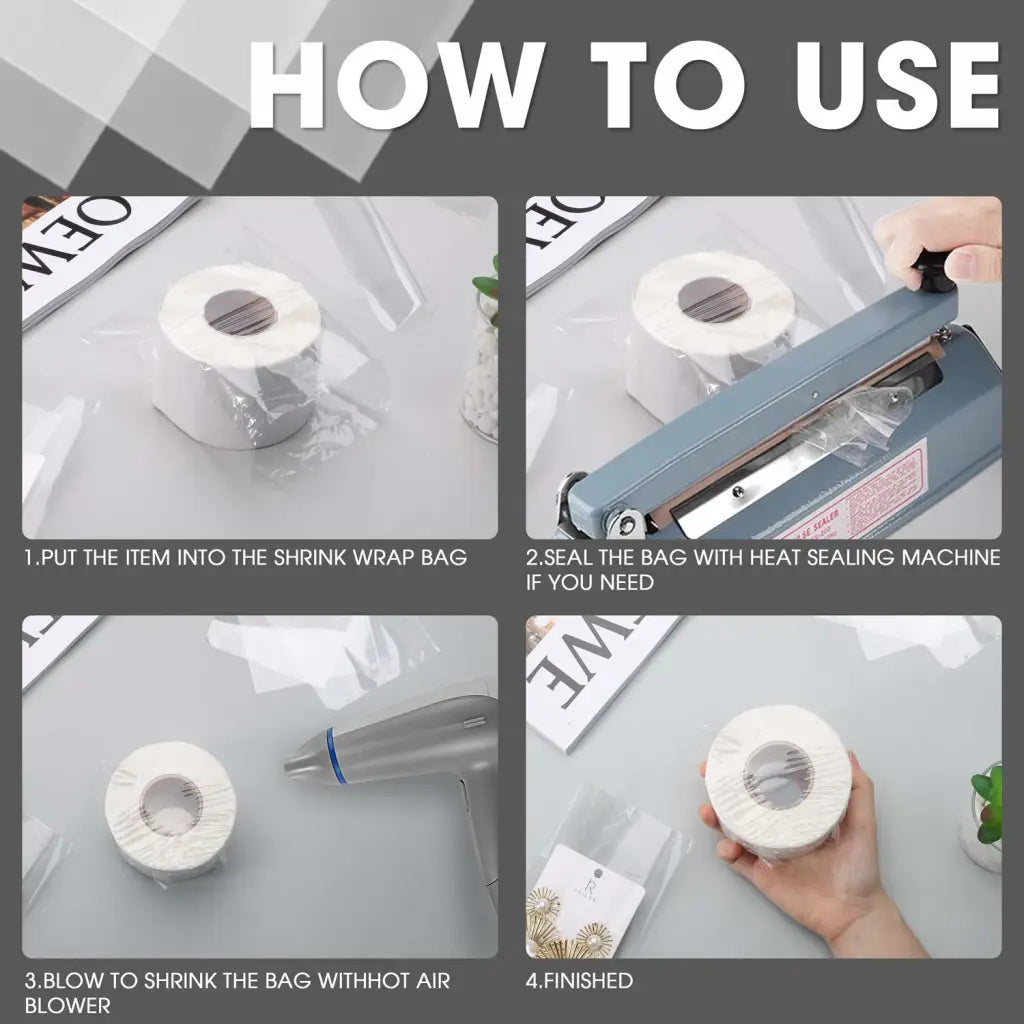

The advantages of employing shrink wrap film in your packaging process are numerous. Its flexibility, strength, recyclability and visual capabilities make it the ideal option for so many types of products and applications. Here are some of the most notable benefits:

* Protection

Shrink film’s durability allows you to protect and preserve the contents of the packaging. Cross-linked films work well for items with sharp edges, as they offer higher tear and puncture resistance, thereby reducing the chances of a package being compromised during shipment. They are also a means of tamper reduction. If you are packaging thousands of items per day and using automatic or semi-automatic wrapping machines, a cross-linked shrink film will help reduce product damage and packaging waste. Furthermore, shrink film helps to increase the shelf life of perishable items and can conceal the smells of the packaging’s contents.

* Presentation

Polyolefin shrink can be customized to the product you are packaging. For added versatility, there are formulations of shrink film perfect for packaging meats or frozen foods. These formulations include barriers to reduce fog (anti-fog) and moisture vapor transmission rate (MVTR).

Shrink film can add a glossy shine to improve visual appeal with your product packaging, and you can print high-quality graphics to gain that much-desired retail visibility. Polyolefin films are optimal for printing a wide array of colors and designs to wrap your product in style or include nutritional information right on the package.

* Sustainability

One of the greatest upsides of POF and PE shrink films is that they are recyclable. As sustainability becomes more important for Consumer Packaged Goods (CPG) businesses of all sizes, it’s critical to adopt packaging materials that meet sustainability standards. In addition, POF shrink film does not release harmful vapors during the heat-sealing process, as PVC does.

* Cost Reduction

By taking advantage of shrink film’s strength and durability, many brands have been able to remove corrugated packaging from their multi-pack products altogether. Heavy products can be securely wrapped in shrink without the need for a corrugated tray. Lightweight items (like single-serve chips) can be packaged in a polybag. This not only helps to reduce the cost of packaging but also minimizes your shelf footprint and opens up space in your facility.

With new technologies becoming available almost daily, you can further optimize your packaging for cost reduction by down-gauging or selecting a lower-width film. If you work with a packaging specialist to conduct a film audit for your packaging line, you’ll see what options are available to you.

At PackedIn, we specialize in providing high-quality protective packaging solutions that ensure your products remain safe during shipping and storage.